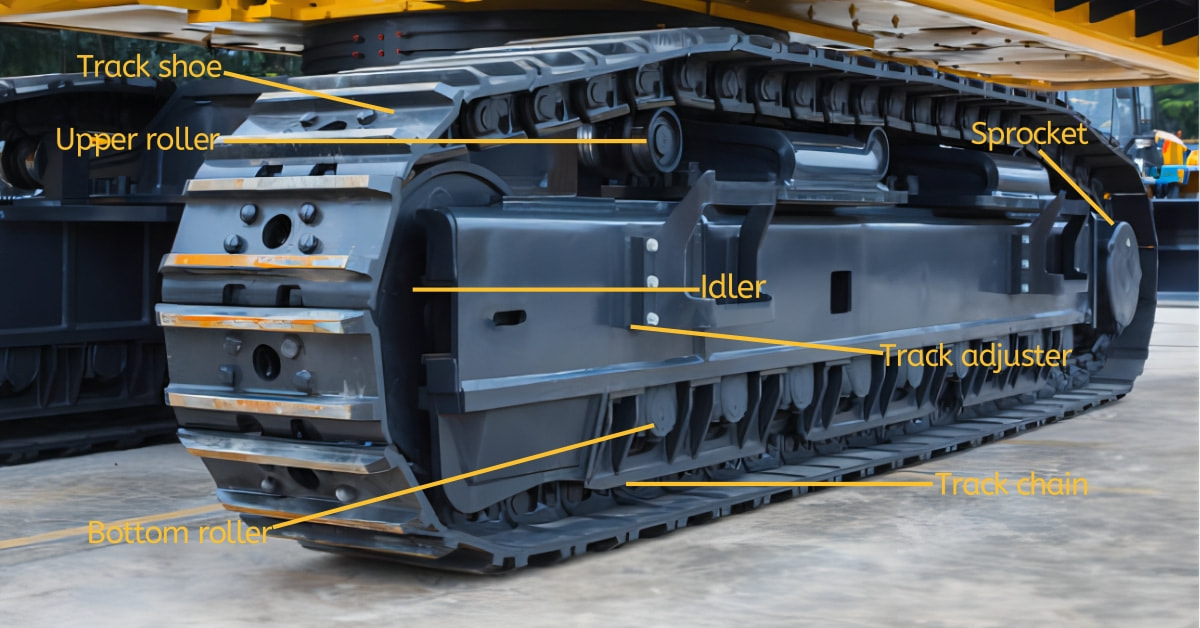

Dozer Undercarriage Parts

Top rollers, also called upper rollers or carrier rollers, are important components in the "four wheels and one track" system of the crawler undercarriage parts for earth moving equipment such as excavators, loaders, crane clawers and bulldozers. The top rollers are located above the track and support the track from above, preventing excessive sagging caused by the track’s own weight or vibrations during movement. This ensures the track maintains proper tension and avoids derailment caused by loosening.

The top rollers are typically made of wear-resistant materials (such as 50Mn or 40Mn2 alloy steel), with their surfaces hardened through quenching (reaching a hardness of HRC 45-52). Their main roles and functions can be summarized as follows:

Top Rollers (Track Carrier rollers), as critical components in the undercarriage or support systems of construction machinery (such as excavators, bulldozers, loaders, etc.), commonly experience the following types of failures:

1. Failures Due to Poor Lubrication

2. Wear and Surface Damage

3. Failures Caused by Improper Installation or Adjustment

4. Structural Damage

Shaft Breakage: Excessive interference fit, fatigue stress concentration, or forging defects may lead to shaft fractures, especially in heavy-duty equipment like rotary kilns.

Cracked Wheel Body: Casting defects or excessive assembly stress can cause cracks in the roller body, particularly in high-temperature environments.

5. External Environmental Factors

Mud or Contaminant Ingress: Prolonged submersion in mud or accumulation of debris around the roller hinders rotation and accelerates seal failure.

Thermal Radiation Effects: High-temperature environments (e.g., near rotary kilns) can degrade lubricants and cause metal thermal deformation.

6. Failures Due to Improper Operation

Poor Track Travel Habits: Driving the excavator with the sprocket in front (when moving forward) increases stress on the carrier rollers, leading to premature failure.

Overloading or Frequent Sharp Turns: Excessive loads or aggressive steering accelerate roller wear.

KASU Parts is a professional manufacturer specializing in undercarriage parts for excavators, bulldozers, loaders, and skid steer loaders. With extensive experience and technical expertise, we offer a wide range of products compatible with leading brands in the market, including Komatsu, Caterpillar, Kobelco, Sumitomo, Bobcat, Volvo, Yanmar, Kubota, John Deere, Case, and more. Our product lineup includes track rollers, chains, carrier rollers, track shoes, idlers, and other essential components, ensuring high quality and reliable performance for various construction machinery.

Below are the part numbers of top rollers for some models, for reference

| Model | OEM Part No. |

| E311/E312 | 417345 |

| E315/E320/E200B | 8E5600 |

| E325/E330 | 102-8152/6Y5323 |

| E450 | 946114 |

| PC60-1 | 103-30-00011 |

| PC60-3/5/6 | 203-30-53001 |

| PC60-7 | 20T-30-00050 |

| PC100-1 | 203-30-00012 |

| PC100-2/3/5 | 203-30-53001 |

| PC100-6 | 203-30-00231 |

| PC120-1/2 | 203-30-00012 |

| PC120-3/5/6 | 203-30-53001 |

| PC200-1/2/3/5/6 | 20Y-30-00022 |

| PC200-7 | 22U-30-00021 |

| PC220-1/2/3/5/6 | 20Y-30-00022 |

| PC300-1/2/3/5/6 | 208-30-00320 |

| PC300-7 | 207-30-00430 |

| PC400-1/2/3/5/6 | 208-30-00320 |

| EX60 | 9062403 |

| EX60-2/3 | 9108841 |

| EX60-5 | 9153288 |

| EX100-1 | 9105752/9061288 |

| EX100-2/3/5 | 9092400 |

| EX120-2/3/5 | 9092400 |

| EX200-1 | 9105751/9062406 |

| EX200-2/3 | 9089636 |

| EX200-5 | 9134245 |

| EX220-1 | 9062406 |

| EX220-2/3 | 9089636 |

| EX220-5 | 9178333 |

| EX270-1/2 | 9062405 |

| EX270-5 | 9149839 |

| EX300-1/2/3 | 9062405 |

| EX300-5/EX330-5 | 9149839 |

| EX400-1 | 9072634 |

| EX400-2/3 | 9099140 |

| EX400-5 | 4349516 |

| SK100-1~3 | 24100N4038F2 |

| SK120-1~3 | 24100N4038F2 |

| SK200-1~3 | 24100N5946F2 |

| SK200-6 | YN64D01022FO |

| SK220-1/2 | 24100N6194F1 |

| SK220-3 | 24100N5946F2 |

| SK300-1 | 24100N3841F2 |

| SK300-2/3 | 24100N7035F1 |

| SH100/SH120 | KNA0592/KNA0625 |

| SH200/SH220 | KRA1251/KRA1302 |

| SH300 | KTA0958 |

| HD700 | 187-50600100 |

| DH200/DH22OLC | 2270-1005 |

| DH280 | 2270-6126 |

| R210 | 81EM-10030-01 |

| R290 | 81E5-2003 |

| EC210 | 1181-00010 |

| EC240 | 1181-00010 |

| EC290 | 1181-00781 |

| EC360 | 1081-04411 |

| EC460 | 1081-04411 |

| D8K | 8P6256/9P2663 |

| D8N | 8E0400 |

| D50-15~18 | 141-30-00110 |

| D60-6 | 141-30-00568 |

| D65EX-12 | 14X-30-00141 |

| D80-18 | 155-30-00233 |

| D150A-1/D155A-1 | 175-30-00515 |

| D3B/D3C | 6S3609 |

| D4 | 6K9880/3K7962 |

| D5H | 6Y3908 |

| D6H/D6R | 6Y1781 |

| D5B/D6B | 9S3570/5A8374 |

| D6C/D6D | 3T3206/9S2730 |

| D7F/D7G | 1P8717/2P3514 |

Why Choose KASU Parts

With many years of experience in the undercarriage parts industry, we have built a strong reputation for delivering stable and reliable quality products. Our expertise ensures that every component meets high standards for durability and performance. We offer competitive pricing without compromising on quality, providing great value to our customers. Additionally, our dedicated after-sales service team is committed to supporting you throughout the entire purchase process and beyond, ensuring your complete satisfaction and peace of mind.

Address : Building 17, Block 9, Section D, 27th Road, Chenghui International Hardware and Electrical City, Xiamei Town, Nan'an City, Quanzhou, Fujian Province

Wechat :

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright © 2025 Quanzhou Futeng Machinery Engineering Co.,Ltd All Rights Reserved.

Sitemap

|

Blog

|

Xml

|

Privacy Policy

Network Supported

Network Supported

Hi! Click one of our members below to chat on